What is a coolant pump?

Water pump it is essential part of cooling system of car motor. Its main function is supporting engine temperature at a stable working diapason. There are two types of water pumps - mechanical and electrical coolant pump. The first type of pumps is more common and used in traditional cooling systems. The main problem of standard pump is that the coolant flow rate is directly proportional to the engine speed. So, it makes some discomfort during heavy traffic during summer, numerous start-stop events, during cold starts.

Benefits from electrical coolant pumps

On the other hand, it is possible to use electrical coolant pump. Such type of pump can also work as an auxiliary pump together with an optimized smaller sized mechanical coolant pump. It is main purpose to move coolant flow through additional coolant circuits to provide cooling to engine while it not working well as during normal vehicle driving.

It has some advantages compared to mechanical one:

- facilitate demand-driven cooling of the vehicle

- saving fuel

- passenger comfort

- contribute to efficient cooling of power train components

- reduce emissions

Function of auxiliary pump

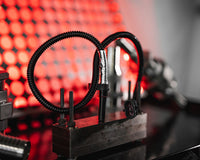

Electrical coolant pump consist of: impeller, inlet, outlet, controller, motor housing, stator, rotor assembly, involute housing.

Pump moved water by way of a bypass hose from the main coolant lines to a radiator-like device. It collects heat and distribute heated air into the vehicle cabin when the heater is turned on. In the other words, auxiliary electrical coolant pump provide heat exchange between coolant and cabin air.

Using electrical pump it is possible to continue heat vehicle when car stopped or for short periods while the driver have to go out from car for some time. The flow boost can help fulfill the requirements during braking applications when the truck is heavily loaded.

The electrical pump’s speed can however be controlled based on the coolant temperature rather than the engine speed, indicating flexibility in designing cooling system components in the future. An electrical pump operating in sync with a smart thermostat valve is the primary step in electrification of the cooling system.

Everything you should know about water pump failure

Auxiliary pump is a quite simple component and in an ideal world, it should work as long as your car. However, sometimes it fails like any electronic component. Blown fuse, damaged wiring, and seized pump – all these can be a reason of water pump failure. In addition, lifetime and condition of the electric engine influence these pumps breakage. What is more, overheating, low coolant, brushes and windings can effect on working capacity of pump.

Consequences of bad auxiliary pump

It is hard to find out that your pump is bad because there is no set inspection for this pump. It is not likely that bad pump will cause overheating of the vehicle. Bad auxiliary pump cannot be a reason of stop, but it can make you journey very uncomfortable in cold winter weather. It is recommended that when you notice alarms bells in car cooling system, you should fix them as soon as possible to avoid the occurrence of larger problems.

Alarm bells for auxiliary pump

To be ready for all possible situation, you need to know how to find out if your water pump is not working properly.

Some warning event to which you should pay attention:

- The first symptom of a problem with an electrical auxiliary pump is cold air that is coming from the heater with the engine off and the key on. If you notice that no hot air is coming into the vehicle, you should contact professional mechanic as soon as you can.

- Heater has fluctuating heat. Temperature changes depending on your driving is not a good sign. Temperature mode in your car should be stable during some time independently of engine work. If the temperature become lower in idle speed, it is also mean problems with auxiliary water pump.

- Fogging window. If your defroster do not work, you should find out why it is not working. This function is assured by the auxiliary water pump operating. Unless you do not feel warm air from the heater core, it means that the auxiliary pump is broken.

- Strange sound under your dashboard. Sometimes the speed of the pump is higher than it should be, or it does not stop working after the engine shut down. Such problem point to an electrical short in the wiring. In this case, it emits a high-pitched buzzing sound.

- Sign of pump working mode is absent. You do not hear how the pump switch on.